Content uploaded by Ran An

Author content

All content in this area was uploaded by Ran An on Dec 26, 2023

Content may be subject to copyright.

Vol.:(0123456789)

1 3

Environmental Earth Sciences (2024) 83:31

https://doi.org/10.1007/s12665-023-11352-w

ORIGINAL ARTICLE

Mechanical behaviour andmicrostructure ofgranite residual

bio‑cemented soil bymicrobially induced calcite precipitation

withdifferent cementation–solution concentrations

RanAn1,3 · HaodongGao2,3 · XianweiZhang3 · XinChen2· YixianWang1· HaoXu2

Received: 9 June 2023 / Accepted: 29 November 2023

© The Author(s), under exclusive licence to Springer-Verlag GmbH Germany, part of Springer Nature 2023

Abstract

Microbially induced calcite precipitation (MICP) stands as an environmentally friendly and promising technique for enhanc-

ing the performance of soil. Bacteria catalyze the hydrolysis of urea, prompting calcium ions to react with carbonate ions,

ultimately forming calcium carbonate precipitation as a cement within soil grains. However, studies of using MICP to enhance

granite residual soil (GRS) that is recognized as a problematic soil because of its wide grain size distribution are relatively

rare. In this present study, bio-cemented GRS samples were prepared through grouting with Sporosarcina pasteurii as the

colony and a mixture of urea and calcium chloride as the cementation solution. The effect of cementation–solution concentra-

tions on the mechanical properties of the bio-cemented samples was analyzed through unconfined compression and triaxial

shear tests. Furthermore, X-ray computerized tomography, scanning electron microscopy, and X-ray diffraction experiments

were performed to reveal the mechanism of MICP from a microscopic perspective. The experimental results indicate that

an optimal concentration of 2mol/L achieved the highest level of cementation, resulting in an impressive 47.15% increase

in the unconfined compressive strength of the GRS samples. The triaxial shear strength and stress paths of bio-cemented

samples were affected by the cementation level. The variation of porosity indicated that CaCO3 precipitation improves soil

densification by filling the macropores among the soil grains. The CaCO3 precipitates from the MICP treatment predomi-

nantly exist in the form of calcite crystals, serving to fill, wrap, and cement within the soil structure, thereby enhancing the

cohesive and frictional forces exerted by the bio-cemented grains.

Keywords MICP· Granite residual soil· Mechanical behaviour· Microstructure· Cementation–solution concentration

Introduction

Used extensively in infrastructure construction in southern

China, granite residual soil (GRS) has a formation process

that is influenced mainly by the prevailing subtropical and

tropical climatic conditions and the properties of the parent

rock (An etal. 2023), and GRS is characterized by having

a wide particle distribution from clay to gravel and a com-

plex primary pore and crack structure (Mohamedzein and

Aboud 2006). Compacted residual soils are commonly used

as filling materials in highway, foundation, and slope con-

struction, and their geotechnical properties play an important

role in engineering stability. However, physical and chemical

weathering greatly affects the properties of residual soils,

* Ran An

anran@wust.edu.cn

* Xianwei Zhang

xwzhang@whrsm.ac.cn

Haodong Gao

ghd0301@outlook.com

Xin Chen

cx2022611@126.com

Yixian Wang

wangyixian2012@hfut.edu.cn

Hao Xu

3321419310@qq.com

1 School ofCivil andHydraulic Engineering, Hefei University

ofTechnology, Hefei, People’sRepublicofChina

2 School ofUrban Construction, Wuhan University ofScience

andTechnology, Wuhan, People’sRepublicofChina

3 State Key Laboratory ofGeomechanics andGeotechnical

Engineering, Institute ofRock andSoil Mechanics,

Chinese Academy ofSciences, Wuhan430071,

People’sRepublicofChina

Environmental Earth Sciences (2024) 83:31

1 3

31 Page 2 of 13

resulting in low strength, high porosity, high permeability,

and easy disintegration in water (An etal. 2022a, b; Liu

etal. 2022). Traditionally, fibers, cements, or polymers are

added to GRS to improve its engineering properties (Okonta

and Nxumalo 2022; Yuan etal. 2022). However, although

using these materials to reinforce GRS is beneficial, doing

so has some negative economic and environmental implica-

tions. Therefore, it is important to seek an environmentally

friendly, energy-saving, and effective method to improve soil

properties.

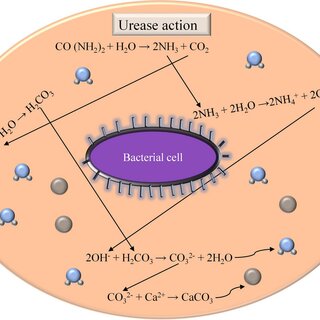

In 1997, Ferris etal. (1997) investigated Sporosarcina

pasteurii which hydrolyzes urea by producing urease and

has become the most commonly used bacteria for micro-

bially induced calcite precipitation (MICP). The carbon-

ate ions produced by the hydrolysis reaction continuously

increase the alkalinity of the reaction solution and com-

bine with calcium ions to produce CaCO3, thereby enhanc-

ing the mechanical properties of the soil (Stocks-Fischer

etal. 1999). In recent years, bio-cementation based on

MICP technology has emerged as an effective and environ-

mentally friendly comprehensive soil utilization technique

(Wani and Mir 2020). The technique of MICP that involves

a complicated biochemical reaction is now used widely

in soil improvement, dust stabilization, wastewater treat-

ment, and heavy-metal remediation (DeJong etal. 2010;

Jain and Dali 2019; Rajasekar etal. 2021; Wani and Mir

2021a), and its microscopic mechanism is briefly depicted

in Fig.1. First, the Sporosarcina pasteurii hydrolyzes urea

into ammonium ions and hydroxide ions in an alkaline

environment. Then, the calcium ions provided by CaCl2

in the cementation solution combine chemically with the

carbonate ions to induce CaCO3 precipitation, which is

an insoluble product with a cementation effect (Canakci

etal. 2015). Finally, the CaCO3 precipitation deposited on

the surface of soil particles enhances the bonding force of

grains (Sasaki and Kuwano 2016). Similarly, MICP tech-

nology can also serve as an effective method for heavy

metal precipitation from wastewater (Torres-Aravena etal.

2018).

In previous cases when MICP was used for soil reinforce-

ment, it was mostly for sandy soils, which have larger grain

size and pore throat size and are more geometrically com-

patible with CaCO3, making it easier to perform MICP by

grouting (Karimian and Hassanlourad 2022). Mujah etal.

(2019) studied the combined effect of bacterial culture and

cementation solution on bio-cemented sand and concluded

that the combination of 3.2mg/mL bacterial cultural and

0.25mol/L cementation solution produced the highest

strength; this is because effective CaCO3 crystals are gener-

ated under these conditions. Chek etal. (2021) treated beach

sand with high-concentration bacterial solution and cemen-

tation solution using surface spraying and percolation, and it

was observed that higher optical density and more bacteria

resulted in lower erodibility and greater crust depth. Jain

and Das (2023) conducted further analysis on the impact of

equal MICP treatment on the biocementation and bioclog-

ging of sands with varying grain sizes and concluded that

the relative size of the soil particles and biominerals deter-

mines the soil strength. Furthermore, due to the formation of

CaCO3 precipitates, MICP can also reduce the permeability

Fig. 1 Microbially induced

calcite precipitation (MICP) by

urease-producing bacteria in the

presence of urea and calcium

chloride

Environmental Earth Sciences (2024) 83:31

1 3

Page 3 of 13 31

of sandy soil by decreasing pore volume and pore size (Gao

etal. 2019; Wani and Mir 2021c).

However, the transport, adsorption, and nucleation

of microorganisms are challenging in fine-grained soils

because of their comparatively tiny particle size and pore

throat size, thus making MICP treatment for fine-grained

soils more challenging. As curing technology has developed,

the microbial treatment of fine-grained soils has achieved a

certain amount of progress. Cardoso etal. (2018) used MICP

in sand containing clay; the results indicated that there was

a chemical interaction between the clay minerals and the

feeding solution, which makes applying MICP to clay more

complicated. Islam etal. (2020) observed that CaCO3 pre-

cipitation increased with increasing clay content, suggesting

that MICP is more effective in soils with higher clay content;

the explanation was the presence of more bacteria in the

clay, and thus it was confirmed that bio-stimulated CaCO3

precipitation can be applied in clay.

The concentration of the cementation solution affects the

cementing effect of MICP to a great extent, including the

production and distribution of CaCO3 precipitation (Stocks-

Fischer etal. 1999; Soon etal. 2014). Al Qabany and Soga

(2013) investigated the effects of cementation–solution con-

centration in the range of 0–1mol/L on the strength and

permeability of cemented soils, and they found that (i) the

unconfined compressive strength (Su) increased with increas-

ing concentration and (ii) low concentration resulted in a

sharp decrease in permeability, whereas high concentra-

tion resulted in a gradual decrease in permeability. Zhao

etal. (2014) discovered that increasing the cementation

concentration from 0.25 to 0.5mol/L increased the Su of

bio-cemented soils tenfold from 0.13 to 1.36MPa, and

increasing the concentration from 0.5 to 1.5mol/L nearly

doubled the Su from 1.36 to 2.13MPa. Besides the strength

properties, Al Qabany etal. (2011) discovered that the

sedimentation pattern is also influenced by concentration.

They observed that lower concentrations tend to distribute

the precipitate better for the same amount of precipitation,

particularly at lower cementation levels. An optimal cemen-

tation–solution concentration is not only a precondition for

large production of CaCO3 precipitation but also provides

the best survival environment for microorganisms during the

MICP treatment process.

Given the numerous adverse engineering properties of

residual soils and their lack of research to date, MICP tech-

nology may be a promising direction in soil enhancement.

To date, numerous studies have focused on improving the

mechanical properties and engineering characteristics of

residual soils using MICP. Soon etal. (2013) compared the

strength enhancement of residual soil and sand by MICP,

and they found that the shear strength of residual soil was

improved significantly more than that of sand under the same

MICP treatment, but the hydraulic conductivity of residual

soil was lower than that of sand. Lee etal. (2013) reported

that MICP treatment led to a noticeable improvement in the

strength and stiffness of residual soil, and they showed that

there was a good correlation between CaCO3 content and

the compression index, peak stress, and total settlement

of the soil, but a poor relationship with the compression

index. However, although some progress has been made in

studying the strength properties and microstructure of soils

after MICP treatment, the factors affecting the MICP effec-

tiveness of GRS are yet to be studied fully, especially the

concentration of the cementation solution. Therefore, more

attention should be paid to applying this method to residual

soils, especially GRS, which is recognized as a problematic

and special soil because of its grain size distribution.

In the present study, the MICP technique was used to

investigate the cementation of GRS by Sporosarcina pas-

teurii with six different concentrations of cementation solu-

tion. The rules of cementation–solution concentrations

affected the mechanical behavior and pore distribution were

analyzed by conducting unconfined compression and triaxial

shear tests, and X-ray computerized tomography. Further-

more, scanning electron microscopy (SEM) experiments

were conducted to reveal the mechanism of soil enhance-

ment by CaCO3 crystals induced by microorganisms, and the

CaCO3 type was identified via X-ray diffraction (XRD) tests.

Materials

Granite residual soil

The samples of GRS used for MICP treatment were col-

lected from a slope in Guilin in Guangxi Province in

China. A set of experiments was conducted to measure

the physical properties of the soil, including its moisture

content (w), dry density (ρd), specific gravity (Gs), void

ratio (e), and Atterberg limits (wp, wL, and Ip). In addition,

the mineral composition was obtained by an XRD test per-

formed according to ASTM D4926-2015 (2015). Table1

lists the basic physical properties and mineral composi-

tion of the studied GRS, which consisted primarily of clay

Table 1 Physical parameters

and mineral composition of

studied GRS

w

(%)

ρd

(g.cm−3)

Gse wL

(%)

wp

(%)

IpMineral composition (%)

Quartz Kaolinite Illite Hematite

35.2 1.49 2.68 1.05 50.5 25.6 24.9 53.8 37.7 5.6 2.9

Environmental Earth Sciences (2024) 83:31

1 3

31 Page 4 of 13

minerals (37.7% kaolinite) and non-clay minerals (53.8%

quartz), indicating that it had undergone intense weather-

ing. The grain size distribution was measured according to

ASTM D422-63 (2002), and as shown in Fig.2, the GRS

contained high contents of clay, silt, and sand particles and

so was characterized as a mixed-grain soil.

Bacterial solution

The bacteria used in this experiment was Sporosarcina pas-

teurii (ATCC 11859) purchased from the China National

General Microbial Species Collection Management Center

(CGMCC). The bacterial solution contained 15-g/L tryp-

tone, 5-g/L peptone, 5-g/L NaCl, and 20-g/L urea, adjusted

to pH7.3 with a 1mol/L NaOH solution. The tryptone,

peptone, and NaCl were autoclaved, and the urea was steri-

lized by ultraviolet light. The bacteria were inoculated into

the medium and then shaken in a constant-temperature

oscillating incubator at 30°C and 130rpm for 36h. The

bacterial medium was centrifuged twice at 4000rpm for

30min, and the suspension was discarded. Fresh medium

was retained for final optical density measurements by a

spectrophotometer at 600nm (OD600 = 0.91). The urease

activity was determined indirectly by measuring the rate

of ammonia production via the Nessler method (Cheng

etal. 2016). The urease activity prepared for this study

was 14.6 U/mL, representing urease present in 1mL of

culture solution could hydrolyze 14.6μmol of urea per

minute. To maintain the viability of the bacterial solution,

it was stored under refrigeration at 4°C and utilized within

1 week (Konstantinou etal. 2021).

Cementation solution

The cementation solution was a mixture of CaCl2 and urea

solution, which provided a calcium source for microbial

cementation and a nitrogen source for microbial growth dur-

ing the MICP process. Urea is hydrolyzed by urease pro-

duced by bacteria to produce carbonate ions, which react

chemically with calcium ions provided by calcium chloride

to produce CaCO3 precipitate. In this study, six different

cementation concentrations with an equal molar ratio of urea

to CaCl2 (0, 0.5, 1.0, 1.5, 2.0, and 2.5mol/L) were used

for the preparation of bio-cemented samples at an ambient

temperature of 20°C and 50% relative humidity.

Methods

MICP treatment

As shown in Fig.3, the soil samples of 50mm diameter and

100mm height for the tests were prepared in a full-contact

PVC pipe with 5-mm-thick filter layers at both ends to pre-

vent seepage of soil. The soil column was compacted by

being vibrated until it reached a dry density of 1.49g/cm3.

Bacterial cultures were introduced into the GRS samples as

an aqueous solution in this study (Fu etal. 2023). To prevent

the clogging of CaCO3 near the injection site, a two-phase

grouting with a peristaltic pump was employed. The effec-

tiveness of this technique has been extensively confirmed by

Whiffin etal. (2007). Initially, the dried sample underwent

an injection of a bacterial solution at a flow rate of 10mL/

min, allowing for the transportation of bacteria through soil

pores via advection and diffusion (Cui etal. 2020). Sub-

sequently, the bacteria were adsorbed onto soil particles.

To enable the bacteria to be in full contact with the soil,

the sample was left for 6h and then injected with one pore

volume of cementation solution at the same rate. After 6h

of curing, the sample was turned upside down carefully and

the above injection procedures were repeated to improve the

uniformity of CaCO3 distribution. A round of grouting was

considered complete when both ends of the sample were

injected, and each sample was subjected to six rounds of

grouting. After the last round of grouting, the chemicals

remaining on the surface of the sample were flushed out with

five pore volumes of deionized water. Finally, the weak parts

of the soil column at both ends were removed and polished

to make a standard sample for mechanical tests.

Unconfined compression strength tests

Unconfined compression strength (UCS) tests performed

according to ASTM D2166/D2166M-16 (2016) were used

to investigate the compressive strength and failure modes of

Fig. 2 Grain-size distribution and soil classification of studied GRS

Environmental Earth Sciences (2024) 83:31

1 3

Page 5 of 13 31

untreated and bio-cemented samples. The UCS instrument

used for these tests was a WDW-100E microcomputer-con-

trolled universal testing machine. During a test, a cylindri-

cal sample was loaded at a rate of 1mm/min until it was

damaged; the stress–strain curve was recorded by the data

acquisition system, and the failure pattern of the sample was

captured by a digital camera.

Consolidated undrained triaxial compression tests

To investigate the mechanical characteristics of the bio-

cemented samples, a GDS triaxial shear device was used to

conduct consolidated undrained compression tests accord-

ing to ASTM D4767-11 (2020). Before testing, the standard

cylindrical samples were washed with distilled water, then

vacuum saturated for 24h, then placed in a pressure chamber

for 24h to consolidate at confining pressures of 50, 100,

200, and 400kPa. Finally, the specimens were subjected to

axial loading at an axial strain rate of 0.01%/min until the

axial strain reached 15%.

X‑ray computerized tomography tests

To investigate the geometrical morphology and distribution

of pores and cracks of untreated and bio-cemented samples,

a series of X-CT tests were performed using a high-resolu-

tion PhoenixV X-CT scanner (General Electric; Wunstorf,

Germany). Grayscale images with a spatial resolution of

20LP/mm were obtained from each scan, and the spatial

porosity was observed after binarisation and three-dimen-

sional (3D) reconstruction of the grayscale images based on

the watershed algorithm.

Scanning electron microscopy tests

The microstructural characteristics and the distribution

of precipitated CaCO3 in the bio-cemented samples were

investigated using SEM. Before testing, all specimens under-

went deionization flushing and were subsequently dried

for 48h. Following this, subsamples with fresh surfaces

were excised from the dehydrated SEM samples and sput-

ter coated with gold alloy to improve their conductivity for

obtaining high-quality SEM images. Finally, the prepared

subsamples were observed via SEM to generate a series of

microscopic images with varying magnifications.

X‑ray diffraction tests

The mineral compositions of both untreated and bio-

cemented samples were analyzed using an X-ray diffractom-

eter (Shimadzu XRD-6000) with Cu Ka radiation at 40kV

and 30mA. Scans were performed from 15° to 65° in steps

of 0.02° at a rate of 0.5s per step.

Results anddiscussion

Effect ofcementation–solution concentration

onunconfined compressive strength

To investigate the strength characteristics of GRS treated

by MICP, untreated and bio-cemented samples with differ-

ent cementation–solution concentrations were subjected

to UCS tests, the results of which are shown in Fig.4. As

can be seen, the stress–strain curves exhibit typical strain-

softening characteristics: initially, the stress of each sample

increases with strain until the peak, after which it decreases

with continually increasing strain. The peak stresses of the

bio-cemented samples are significantly higher than that

of the untreated sample, and the peak stress of the bio-

cemented sample with 2mol/L cementation solution is the

highest among all the samples. This indicates that there

is an optimum cementation solution of 2mol/L for a bio-

cemented sample to obtain a maximum peak stress as the

Fig. 3 a Schematic of MICP treatment; b photograph of grouting devices

Environmental Earth Sciences (2024) 83:31

1 3

31 Page 6 of 13

cementation–solution concentration is increased from zero

to 2.5mol/L.

Figure5 shows the effects of the cementation–solution

concentration on the Su and elastic modulus (E) of the bio-

cemented samples. As can be seen, applying MICP with

the optimum cementation–solution concentration greatly

improves the strength characteristics of GRS. As shown in

Fig.5, Su and E of the bio-cemented sample with 2mol/L

cementation solution increased by 47.15% and 82.08%,

respectively. The increases in Su and E indicate the forma-

tion of CaCO3 crystals between soil particles, which can

develop structural continuity in the appropriate alkaline

environment. However, the Su and E of the bio-cemented

sample with 2.5mol/L cementation solution decreased. This

may be due to the inhibition of the generation of enzymes

necessary for bacterial functional metabolism. In addition

to inhibiting microbial activity, a higher concentration

cementation solution also impairs the efficiency of CaCO3

precipitation (Kunst and Rapoport 1995; Rivadeneyra etal.

2020). Previous investigations have demonstrated that bacte-

rial growth and metabolism can be inhibited in urea–Ca2+

cementation solutions when concentrations exceed a specific

threshold (Nekolny and Chaloupka 2000; Tang etal. 2020).

For instance, in the case of dredged river silt, the greatest

enhancement in strength and elastic modulus was observed

when the concentration of the cementing solution reached

1.5mol/L, and for soft clay and sandy soil, optimal cemen-

tation–solution concentrations were found to be 0.5mol/L

and 1mol/L, respectively (Van Paassen 2009; Xiao etal.

2020; Wang etal. 2022). However, in this experiment, the

Su and E of the bio-cemented sample decreased when the

cementation–solution concentration exceeded 2mol/L, and

the soil type, microbe species, optical densities, and ambient

temperature are considered to be factors influencing these

differences (Bosak etal. 2004; Ferris etal. 2004; Dhami

etal. 2013; Kim etal. 2013; Wani and Mir 2021b; Mir and

Wani 2021; Jain 2023).

Moreover, as a result of microbial cementation, MICP

transformed the failure mode of the GRS from plastic to

brittle, aligning with Tang etal. (2020) who observed that

MICP-treated soils generally exhibit more brittle charac-

teristics. Figure6 shows damage photographs and failure

patterns of the bio-cemented samples with different cemen-

tation levels. The untreated and weakly cemented samples

exhibited failure patterns of local cracks due to insufficient

cohesion (Fig.6a, b). When the concentration was increased

slightly, the plastic failure of the bio-cemented samples was

markedly weakened (Fig.6c, d). Comparing the failure pat-

terns of the two bio-cemented samples shown in Fig.6e, f

shows that the one with 2mol/L cementation solution exhib-

ited a more significant brittle failure (although both samples

showed similar integral shear damage), which confirms that

the optimum cementation–solution concentration promotes

the microbial cementing capacity, contributing to the full

performance of MICP in enhancing GRS. Taken together,

these results indicate that bio-cemented samples treated with

cementation–solution concentrations increasing from zero

to 2.0mol/L develop higher compressive parameters and,

therefore, form a stronger structure.

Effect ofcementation–solution concentration

onshear strength

With shear strength being a governing design parameter

for geotechnical engineering structures, there have been

numerous studies of microbial cementation for improving

the shear strength properties of soils (Arpajirakul etal.

0

50

100

150

200

0123456

Axial stress (kPa)

Axial strain (%)

0 mol/L

0.5 mol/L

1.0 mol/L

1.5 mol/L

2.0 mol/L

2.5 mol/L

Fig. 4 Stress–strain curves of untreated and bio-cemented samples

Unconfined compressive strength

Elastic modulus

0 0.5 1 1.5 2 2.5

100

120

140

160

180

200

220

Concentration (mol/L)

S

u

(kPa)

0

2

4

6

8

10

E (MPa)

Fig. 5 Effects of cementation–solution concentration on parameters

from UCS tests

Environmental Earth Sciences (2024) 83:31

1 3

Page 7 of 13 31

2021; Sharma etal. 2022). Figure7 indicates that the

stress–strain curves for untreated and bio-cemented sam-

ples all exhibit strain-hardening (Cui etal. 2017). In gen-

eral, with increasing axial strain, the axial stress increases

sharply initially and then stabilizes. The stress–strain

curves of all samples are featured by strain-hardening

and are influenced markedly by the confining pressure;

specifically, as the confining pressure is increased from

50 to 400kPa, the stress–strain curves move consistently

upward.

Fig. 6 Failure modes of bio-cemented samples with different cementation concentrations: a zero; b 0.5 mol/L; c 1.0 mol/L; d 1.5 mol/L; e

2.0mol/L; f 2.5mol/L

Fig. 7 Stress–strain curves of bio-cemented samples with various cementation–solution concentrations: a zero; b 0.5 mol/L; c 1.0 mol/L; d

1.5mol/L; e 2.0mol/L; f 2.5mol/L

Environmental Earth Sciences (2024) 83:31

1 3

31 Page 8 of 13

The theory of Mohr–Coulomb provides the basis for cal-

culating the shear strength parameters of soils. In the case of

testing data for the untreated and bio-cemented with 2mol/L

cementation solution samples, the Mohr circles and shear

strength envelopes are presented in Fig.8. The Mohr circles

exhibited that as the mean stress increases, the shear strength

rises linearly. In addition, the shear envelope moves upward

with increasing cementation level. The slope of the stress

paths increases, because the soil densification was enhanced

under the impact of microbial cementation (DeJong etal.

2010). The six sets of effective stress parameters (c' and φ')

calculated based on the Mohr–Coulomb theory are listed

in Table2. The effective cohesion of the bio-cemented

samples with different cementation–solution concentra-

tions (0.5, 1.0, 1.5, 2.0, 2.5mol/L) increases by 29.15%,

66.36%, 94.85%, 127.62%, and 122.27%, respectively. In

the range of 0.5–2.5mol/L for the cementation solution, the

internal friction angle is higher than that of the untreated

sample, increasing by 9.97%, 19.01%, 26.53%, 36.50%, and

33.19%, respectively. Note that the bio-cemented sample

with 2mol/L concentration solution has the greatest increase

in shear strength, which is consistent with the analysis of its

Su and E. The results show that MICP treatment enhances

the shear behavior of GRS by increasing both its effective

cohesion and internal friction angle. This is because CaCO3

precipitates can be considered as particle-wrapping materials

that improve the surface roughness of soil particles and thus

increase the effective internal friction angle. Meanwhile,

CaCO3 crystals can also be considered as particle-binding

materials that increase the effective cohesion because of the

enhanced binding strength between soil particles.

Effect ofcementation–solution concentration

onpore size distribution

Through X-ray computed tomography scans of the bio-

cemented samples, changes in their densification can be

estimated by visualization and quantitative analysis. 3D

models of the pore structures in Fig.9 were reconstructed

from X-CT images. It is clear that the pore sizes of the bio-

cemented samples are reduced greatly and the total pore vol-

umes are smaller when the concentration exceeds 1.5mol/L.

Elliot etal. (2007) used the pore size classifications of

5–30μm, 30–100μm, 100–1000μm, and 1000–2000μm,

an approach that has been used widely. Combined with the

present X-CT test results, the 3D pore sizes were divided

into four intervals: micropores (≤ 100 μm), mesopores

(100–500μm), macropores (500–1000μm), and intercon-

nected cracks (≥ 1000μm). The distribution of pore sizes

was affected by the cementation level for the bio-cemented

samples, as shown in Fig.10. In general, compared to the

untreated sample, the bio-cemented samples had fewer

macropores and interconnected cracks, but more mesopores

and micropores. In addition, the cracks in bio-cemented

samples gradually transformed into mesopores and micropo-

res with the increase of concentration–solution concentra-

tion. In addition, this change was most obvious when the

concentration reached 2mol/L. The reason for the change in

pore size distribution is that the CaCO3 precipitates mainly

occupy macropores and cracks to reduce pore sizes. As a

result, this eventually appears as an enhancement in the soil

densification. The analysis of pore size distribution shows

the feasibility of filling the voids in GRS bio-cemented by

MICP treatment.

Effects ofcementation–solution concentration

onmicrostructure andmineral composition

To reveal the mechanism for the solidification of MICP

treatment, the microscopic characteristics of an untreated

sample and one bio-cemented with 2mol/L cementation

solution were analyzed using SEM images obtained with dif-

ferent magnifications. As shown in Fig.11a for the untreated

sample, the soil particles were arranged loosely and the fis-

sures were larger. By contrast, as shown in Figs.11b and

11c for the bio-cemented sample, CaCO3 crystals were inte-

grated into the entire soil structure, cementing adjacent soil

0 300 600 900 1200 1500

0

200

400

600

800

1000

τ´(kPa)

σ´ (kPa)

C0-50 kPa

C0-100 kPa

C0-200 kPa

C0-400 kPa

C2.0-50 kPa

C2.0-100 kPa

C2.0-200 kPa

C2.0-400 kPa

τ´=44.66+σ´·tan32.16°

τ´=19.62+σ´·tan24.56°

Fig. 8 Shear strength envelope and Mohr circles of soils from triaxial

shear tests

Table 2 Parameters of strength

characteristics of untreated and

bio-cemented samples

Concentra-

tion (mol/L)

c´ (kPa) φ´ (°)

0 19.62 23.56

0.5 25.34 25.91

1.0 32.64 28.04

1.5 38.23 29.81

2.0 44.66 32.16

2.5 43.61 31.38

Environmental Earth Sciences (2024) 83:31

1 3

Page 9 of 13 31

particles tightly together and there were fewer fissures in

the bio-cemented sample. This is also consistent with the

microscopic observations made by Wani and Mir (2020),

which indicate that CaCO3 binds to stabilize soil parti-

cles and increases flocculation. As shown in Fig.11d, the

CaCO3 crystals—which are mostly irregular spheres—are

distributed mainly in the internal pores, on the surfaces,

and contact points of the soil particles. Formed from MICP,

the CaCO3 crystals play the roles of filling, wrapping, and

cementing (Tian etal. 2022): filling means that CaCO3 crys-

tals are precipitated in the internal pores between coarse

particles, which makes the soil more compact and thus

increases its shear strength; wrapping refers to CaCO3 crys-

tals on the surfaces of soil particles improving the roughen-

ing of the soil, thereby increasing its internal friction angle;

cementing means that the CaCO3 precipitation enlarges the

contact regions of the soil particles, thereby increasing the

cohesive strength of the soil microstructure.

The changes in mineral composition were confirmed by

XRD tests. Previous work showed that three main types of

CaCO3 are produced during MICP, i.e., calcite, vaterite, and

amorphous (Zhang etal. 2020). The physical and mechani-

cal properties of calcite are the most stable, but bacterial

activation and the rate of urea hydrolysis may affect the crys-

tallization of CaCO3. To analyze the mineral types of the

microbially induced crystals, XRD tests were performed on

an untreated sample and one bio-cemented with 2.0mol/L

cementation solution. As shown in Fig.12, the mineral com-

position of the untreated sample was mainly quartz, kaolin-

ite, illite, and hematite; after MICP treatment, calcite with

Fig. 9 3D pore models of various bio-cemented samples: a zero; b 0.5mol/L; c 1.5mol/L; d 2.0mol/L

Environmental Earth Sciences (2024) 83:31

1 3

31 Page 10 of 13

a content of 4.9% appeared in the bio-cemented sample, but

its XRD spectrum shows no vaterite or amorphous CaCO3,

which confirms that the CaCO3 precipitates in MICP-treated

GRS are calcite crystals.

Conclusions

To examine the potential of using MICP to enhance GRS,

laboratory tests were performed on samples of GRS bio-

cemented with six groups of cementation–solution concen-

trations. The optimum cementation–solution concentration

was determined for the highest improvement in the mechani-

cal properties of the GRS. The pore distribution and distri-

bution and types of CaCO3 crystals produced during MICP

were studied to analyze the mechanism of MICP action.

Based on the experimental results, the following conclu-

sions are drawn.

(1) From uniaxial compression tests, the largest

increases in Su and E were 47.15% and 82.08%, respec-

tively, for the bio-cemented sample with 2 mol/L

Fig. 10 Pore size distributions of untreated and bio-cemented samples

Fig. 11 SEM micrographs and schematic: a untreated sample (2000 × magnification); b bio-cemented sample (2000 × magnification); c bio-

cemented sample (5000 × magnification); d distribution of CaCO3 in soil

Environmental Earth Sciences (2024) 83:31

1 3

Page 11 of 13 31

cementation solution, this being the optimum concen-

tration for MICP treatment. The compressive strength

decreased as the cementation–solution concentration was

increased up to 2.5mol/L, this being because higher con-

centration not only inhibited the efficiency of CaCO3 for-

mation but also affected the activity of the microorganisms

and the production of enzymes required for their metabo-

lism. The failure pattern of untreated and bio-cemented

samples under uniaxial compression changed from plastic

to brittle, indicating that CaCO3 precipitation enhanced

the integrity of the samples.

(2) The triaxial test results showed that the cementa-

tion level had a significant effect on stress paths of the bio-

cemented samples. Specifically, the bio-cemented sample

with the optimum concentration had the largest increase in

ultimate deviator stress compared to that of the untreated

sample. Being ascribed to the enhancing bonding degree

of soil particles, the increases in its effective cohesion and

internal friction angle of the bio-cemented samples with

2mol/L cementation solution were the largest, at 127.62%

and 36.50%, respectively.

(3) The X-ray CT-based analysis of the pore size dis-

tribution of GRS before and after MICP treatment showed

that the CaCO3 precipitation mainly filled macropores and

interconnected cracks. This variation of porosity indicates

that CaCO3 precipitation improved the densification of the

GRS samples.

(4) The action mechanism for the change in mechanical

properties of GRS after MICP was analyzed microscopi-

cally. CaCO3 precipitation was distributed mainly in pores

or on the surfaces and contact points of particles, acting as

filling, wrapping, and cementing, respectively. Besides, the

results of XRD spectra confirmed that the CaCO3 precipi-

tates were calcite crystals, which have stable physical and

mechanical properties.

Acknowledgements The present study had the financial support of the

National Natural Science Foundation of China (Grant Nos. 12102312

and 42177148), Institute of Rock and Soil Mechanics, Chinese Acad-

emy of Sciences (SKLGME021018), and the Open Fund of State Key

Laboratory of Geohazard Prevention and Geoenvironment Protection

(SKLGP2021K011). The authors are grateful for the help form anony-

mous editors and reviewers.

Authors' contributions All authors contributed to the study concep-

tion and design. Writing—original draft preparation: RA, HG, XZ;

writing—review and editing: RA, HG, XC; data collection and analy-

sis: RA, HG, YW; methodology: RA, HG, HX. All authors read and

approved the final manuscript.

Data Availability Data will be made available on request.

Declarations

Competing interests The authors declare no competing interests.

Conflict of interest The authors declare that they have no known com-

peting financial interests or personal relationships that could have ap-

peared to influence the work reported in this paper.

References

Al Qabany A, Soga K (2013) Effect of chemical treatment used in

MICP on engineering properties of cemented soils. Geotech

63(4):331–339. https:// doi. org/ 10. 1680/ bcmpge. 60531. 010

Al Qabany A, Soga K, Santamarina C (2012) Factors affecting effi-

ciency of microbially induced calcite precipitation. J Geotech

Geoenviron Eng 138(8):992–1001. https:// doi. org/ 10. 1061/

(ASCE) GT. 1943- 5606. 00006 66

An R, Kong LW, Zhang XW, Li CS (2022a) Effects of dry-wet cycles

on three-dimensional pore structure and permeability character-

istics of granite residual soil using X-ray micro computed tomog-

raphy. J Rock Mech Geotech Eng 14(3):851–860. https:// doi. org/

10. 1016/j. jrmge. 2021. 10. 004

An R, Wang YX, Zhang XW, Chen C, Liu XY, Cai ST (2023) Quantita-

tive characterization of drying-induced cracks and permeability of

Fig. 12 Mineral compositions:

a X-ray spectra of untreated

and bio-cemented samples; b

mineral content of untreated

sample; c mineral content of

bio-cemented sample

20 30 40 50 60

0

500

1000

1500

Intensity (a.u)

Diffraction angle 2θ (°)

Q

KIC

QH

K: Kaolinite

I: Illite

Q: Quartz

H: Hamatite

C: Calcite

Untreated sample

Bio-cemented sample

(b)

(c)

K

K

Q

I

K

I

I

QH

(a)

K:35.9%

H:2.6%

Q:52.1%

I:4.5%

C:4.9%

I:5.6%

Q:53.8%

H:2.9%

K:37.7%

Environmental Earth Sciences (2024) 83:31

1 3

31 Page 12 of 13

granite residual soil using micron-sized X-ray computed tomogra-

phy. Sci Total Environ 876(10):163213. https:// doi. org/ 10. 1016/j.

scito tenv. 2023. 163213

An R, Zhang XW, Wang YX, Liu XY, Chen C, Gong JW (2022b)

Freeze-thaw impact on sandy clay in artificial frozen walls: an

investigation of shear strength and pore-size distribution. Int J

Geomech 22(12). https:// doi. org/ 10. 1061/ (ASCE) GM. 1943- 5622.

00024 89

Arpajirakul S, Pungrasmi W, Likitlersuang S (2021) Efficiency of

microbially-induced calcite precipitation in natural clays for

ground improvement. Constr Build Mater 282:122722. https://

doi. org/ 10. 1016/j. conbu ildmat. 2021. 122722

ASTM D2166/D2166M-16 (2016) Standard test method for unconfined

compressive strength of cohesive soil. American Society for Test-

ing and Materials

ASTM D422–63 (2002) Standard test method for particle-size analysis

of soils. American Society for Testing and Materials

ASTM D4767–11 (2020) Standard test method for consolidated und-

rained triaxial compression test for cohesive soils. American Soci-

ety for Testing and Materials

ASTM D4926–15 (2015) Standard test method for gamma alumina

content in catalysts and catalyst carriers containing silica and alu-

mina by X-Ray powder diffraction. American Society for Testing

and Materials

Bosak T, Souza-Egipsy V, Corsetti FA, Newman DK (2004) Microm-

eter-scale porosity as a biosignature in carbonate crusts. Geol

32(9):781–784. https:// doi. org/ 10. 1130/ G20681.1

Canakci H, Sidik W, Kilic IH (2015) Effect of bacterial calcium car-

bonate precipitation on compressibility and shear strength of

organic. Soils Found 55:1211–1221. https:// doi. org/ 10. 1016/j.

sandf. 2015. 09. 020

Cardoso R, Pires I, Duarte SO, Monteiro GA (2018) Effects of clay’s

chemical interactions on biocementation. Appl Clay Sci 156:96–

103. https:// doi. org/ 10. 1016/j. clay. 2018. 01. 035

Chek A, Crowley R, Ellis TN, Durnin M, Wingender B (2021) Evalua-

tion of factors affecting erodibility improvement for MICP-treated

beach sand. J Geotech Geoenviron Eng 147(3):04021001. https://

doi. org/ 10. 1061/ (ASCE) GT. 1943- 5606. 00024 81

Cheng L, Shahin MA, Cord-Ruwisch R (2016) Surface percolation

for soil improvement by biocementation utilizing insitu enriched

indigenous aerobic and anaerobic ureolytic soil microorganisms.

Geomicrobiol J 34(6):546–556. https:// doi. org/ 10. 1080/ 01490 451.

2016. 12327 66

Choi SG, Hoang T, Alleman EJ, Chu J (2019) Splitting tensile strength

of fiber-reinforced and biocemented sand. J Geotech Geoenviron

Eng 31(9):06019007. https:// doi. org/ 10. 1061/ (ASCE) MT. 1943-

5533. 00028 41

Cui MJ, Zheng JJ, Zhang RJ, Lai H (2020) Soil bio-cementation using

an improved 2-step injection method. Arab J Geosci 13:1270.

https:// doi. org/ 10. 1007/ s12517- 020- 06168-y

Cui MJ, Zheng JJ, Zhang RJ, Lai HJ, Zhang J (2017) Influence of

cementation level on the strength behaviour of bio-cemented

sand. Acta Geotech 12(5):971–986. https:// doi. org/ 10. 1007/

s11440- 017- 0574-9

DeJong JT, Mortensen BM, Martinez BC, Nelson DC (2010) Bio-

mediated soil improvement. Ecol Eng 36(2):197–210. https:// doi.

org/ 10. 1016/j. ecole ng. 2008. 12. 029

Dhami NK, Reddy MS, Mukherjee A (2013) Biomineralization of cal-

cium carbonate polymorphs by the bacterial strains isolated from

calcareous sites. J Microbiol Biotechnol 23(5):707–714. https://

doi. org/ 10. 4014/ jmb. 1212. 11087

Elliot TR, Heck RJ (2007) A comparison of optical and X-ray CT

technique for void analysis in soil thin section. Geoderma 141(1–

2):60–70. https:// doi. org/ 10. 1016/j. geode rma. 2007. 05. 001

Ferris FG, Phoenix V, Fujita Y, Smith RW (2004) Kinetics of cal-

cite precipitation induced by ureolytic bacteria at 10 to 20 C in

artificial groundwater. Geochim Cosmochim Act 68(8):1701–

1710. https:// doi. org/ 10. 1016/ S0016- 7037(03) 00503-9

Ferris FG, Stehmeier LG, Kantzas A, Mourits FM (1997) Bacterio-

genic mineral plugging. J Can Pet Technol 36(09). https:// doi.

org/ 10. 2118/ 97- 09- 07

Fu TZ, Saracho AC, Haigh SK (2023) Microbially induced carbonate

precipitation (MICP) for soil strengthening: A comprehensive

review. Biogeotechnics 1(1):100002. https:// doi. org/ 10. 1016/j.

bgtech. 2023. 10000

Gao YF, Tang XY, Chu J, He J (2019) Microbially induced calcite

precipitation for seepage control in sandy soil. Geomicrobiol J

36(4):366–375. https:// doi. org/ 10. 1080/ 01490 451. 2018. 15567 50

Harkes MP, Van Paassen LA, Booster JL, Whiffin VS, Van Loosdrecht

M (2010) Fixation and distribution of bacterial activity in sand to

induce carbonate precipitation for ground reinforcement. Ecol Eng

36(2):112–117. https:// doi. org/ 10. 1016/j. ecole ng. 2009. 01. 004

Islam MT, Chittoori BC, Burbank M (2020) Evaluating the applicabil-

ity of biostimulated calcium carbonate precipitation to stabilize

clayey soils. J Mater Civ Eng 32(3):04019369. https:// doi. org/ 10.

1061/ (ASCE) MT. 1943- 5533. 00030 36

Jain S (2023) Suitability of various ureolytic microbes for potential soil

strengthening via biocementation. J Hazard Toxic Radioact Waste

28(1). https:// doi. org/ 10. 1061/ JHTRBP. HZENG- 1233

Jain S, Dali NA (2019) Biochemically Induced Carbonate Precipita-

tion in Aerobic and Anaerobic Environments by Sporosarcina

pasteurii. Geomicrobiol J 36:443–451. https:// doi. org/ 10. 1080/

01490 451. 2019. 15691 80

Jain S, Das SK (2023) Influence of size and concentration of carbon-

ate biomineral on biocementation and bioclogging for mitigating

soil degradation. Biogeotechnics 1(2):100021. https:// doi. org/ 10.

1016/j. bgtech. 2023. 100021

Karimian A, Hassanlourad M (2022) Mechanical behaviour of MICP-

treated silty sand. Bull Eng Geol Environ 81:285. https:// doi. org/

10. 1007/ s10064- 022- 02780-2

Kim D, Park K, Kim D (2013) Effects of ground conditions on micro-

bial cementation in soils. Mater 7(1):143–156. https:// doi. org/ 10.

3390/ ma701 0143

Konstantinou C, Wang Y, Biscontin G, Soga K (2021) The role of bac-

terial urease activity on the uniformity of carbonate precipitation

profiles of bio-treated coarse sand specimens. Sci Rep 11:6161.

https:// doi. org/ 10. 1038/ s41598- 021- 85712-6

Kunst F, Rapoport G (1995) Salt stress is an environmental signal

affecting degradative enzyme synthesis in Bacillus subtilis. J

Bacteriol 177(9):2403–2407. https:// doi. org/ 10. 1128/ jb. 177.9.

2403- 2407. 1995

Lee ML, Ng WS, Tanaka Y (2013) Stress-deformation and compress-

ibility responses of bio-mediated residual soils. Ecol Eng 60:142–

149. https:// doi. org/ 10. 1016/j. ecole ng. 2013. 07. 034

Liu XY, Zhang XW, Kong LW, Wang G, Lu JF (2022) Disintegration

of granite residual soils with varying degrees of weathering. Eng

Geol 305:106723. https:// doi. org/ 10. 1016/j. enggeo. 2022. 106723

Mir BA, Wani KMNS (2021) Effective use of microbes in waste soil

stabilisation considering natural temperature variations. Geomech

Geoengin 17(6):1941–1961. https:// doi. org/ 10. 1080/ 17486 025.

2021. 19814 65

Mohamedzein YEA, Aboud MH (2006) Compressibility and shear

strength of a residual soil. Geotech Geol Eng 24(5):1385–1401.

https:// doi. org/ 10. 1007/ s10706- 005- 2630-8

Mujah D, Cheng L, Shahin MA (2019) Microstructural and geome-

chanical study on biocemented sand for optimization of MICP

process. J Mater Civ Eng 31(4):04019025. https:// doi. org/ 10.

1061/ (ASCE) MT. 1943- 5533. 00026 60

Nekolny D, Chaloupka J (2000) Protein catabolism in growing Bacil-

lus megaterium during adaptation to salt stress. FEMS Microbiol

Lett 184(2):173–177. https:// doi. org/ 10. 1111/j. 1574- 6968. 2000.

tb090 10.x

Environmental Earth Sciences (2024) 83:31

1 3

Page 13 of 13 31

Okonta FN, Nxumalo SP (2022) Strength properties of lime stabilized

and fibre reinforced residual soil. Geomech Eng 28(1):35–48.

https:// doi. org/ 10. 12989/ gae. 2022. 28.1. 035.Rajasekar A, Wilkin-

son S, Moy CK (2021) MICP as a potential sustainable technique

to treat or entrap contaminants in the natural environment: a

review. Environ Sci Ecotechnol 6:100096. https:// doi. org/ 10.

1016/j. ese. 2021. 100096

Rivadeneyra MA, Delgado G, Soriano M, Ramos-Cormenzana A,

Delgado R (2000) Precipitation of carbonates by Nesterenkonia

halobia in liquid media. Chemosphere 41(4):617–624. https:// doi.

org/ 10. 1016/ S0045- 6535(99) 00496-8

Sasaki T, Kuwano R (2016) Undrained cyclic triaxial testing on sand

with non-plastic fines content cemented with microbially induced

CaCO3. Soils Found 56(3):485–495. https:// doi. org/ 10. 1016/j.

sandf. 2016. 04. 014

Sharma M, Satyam N, Reddy KR (2022) Comparison of improved

shear strength of biotreated sand using different ureolytic strains

and sterile conditions. Soil Use Manage 38(1):771–789. https://

doi. org/ 10. 1111/ sum. 12690

Soon NW, Lee LM, Khun TC, Ling HS (2013) Improvements in engi-

neering properties of soils through microbial-induced calcite

precipitation. J Mater Civ Eng 17(4):718–728. https:// doi. org/ 10.

1007/ s12205- 013- 0149-8

Soon NW, Lee LM, Khun TC, Ling HS (2014) Factors affecting

improvement in engineering properties of residual soil through

microbial-induced calcite precipitation. J Geotech Geoenviron

Eng 140(5):04014006. https:// doi. org/ 10. 1061/ (ASCE) GT. 1943-

5606. 00010 89

Stocks-Fischer S, Galinat JK, Bang SS (1999) Microbiological precipi-

tation of CaCO3. Soil Biol Biochem 31(11):1563–1571. https://

doi. org/ 10. 1016/ S0038- 0717(99) 00082-6

Tang CS, Yin LY, Jiang NJ, Zhu C, Zeng H, Li H, Shi B (2020) Factors

affecting the performance of microbial-induced carbonate pre-

cipitation (MICP) treated soil: a review. Environ Earth Sci 79:94.

https:// doi. org/ 10. 1007/ s12665- 020- 8840-9

Tian XW, Xiao HB, Li ZX, Li ZY, Su HY (2022) Ouyang Q (2022)

Experimental study on the strength characteristics of expansive

soils improved by the MICP method. Geofluids 3:1–10. https://

doi. org/ 10. 1155/ 2022/ 30898 20

Torres-Aravena AE, Duarte-Nass C, Azócar L, Mella-Herrera R, Rivas

M, Jeison D (2018) Can microbially induced calcite precipitation

(MICP) through a ureolytic pathway be successfully applied for

removing heavy metals from wastewaters? Crystals 8(11):438.

https:// doi. org/ 10. 3390/ cryst 81104 38

Van Paassen LA (2009) Biogrout, ground improvement by microbial

induced carbonate precipitation. Delft University of Technology,

Delft

Wang YK, Wang G, Wan YK, Yu X, Zhao JC, Shao JG (2022) Recy-

cling of dredged river silt reinforced by an eco-friendly technol-

ogy as microbial induced calcium carbonate precipitation (MICP).

Soils Found 62(6):101216. https:// doi. org/ 10. 1016/j. sandf. 2022.

101216

Wani KMNS, Mir BA (2021a) An experimental study on the bio-

cementation and bio-clogging effect of bacteria in improving

weak dredged soils. Geotech Geol Eng 39:317–334. https:// doi.

org/ 10. 1007/ s10706- 020- 01494-0

Wani KMNS, Mir BA (2021b) Effect of microbial stabilization on the

unconfined compressive strength and bearing capacity of weak

soils. Transp Infrastruct Geotech 8:59–87. https:// doi. org/ 10. 1007/

s40515- 020- 00110-1

Wani KMNS, Mir BA (2021c). A Laboratory-scale study on the bio-

cementation potential of distinct river sediments infused with

microbes. Transp Infrastruct Geotech 8:162–185. https:// doi.

org/ 10. 1007/ s40515- 020- 00131- wWani KMNS, Mir BA (2022)

Application of bio-engineering for marginal soil improvement:

an eco-friendly ground improvement technique. Indian Geotech J

52:1097–1115. https:// doi. org/ 10. 1007/ s40098- 022- 00639-7

Wani KSNS, Mir BA (2020) Unconfined compressive strength test-

ing of bio-cemented weak soils: a comparative upscale laboratory

testing. Arab J Sci Eng 45:8145–8157. https:// doi. org/ 10. 1007/

s13369- 020- 04647-8

Whiffin VS, Van Paassen LA, Harkes MP (2007) Microbial carbonate

precipitation as a soil improvement technique. Geomicrobiol J

24(5):417–423. https:// doi. org/ 10. 1080/ 01490 45070 14365 05

Xiao JZ, Wei YQ, Cai H, Wang ZW, Yang T, Wang QH, Wu SF (2020)

Microbial-induced carbonate precipitation for strengthening soft

clay. Adv Mater Sci Eng 2020:8140724. https:// doi. org/ 10. 1155/

2020/ 81407 24

Yuan B, Chen W, Zhao J, Yang F, Luo Q (2022) Chen T (2022) The

effect of organic and inorganic modifiers on the physical proper-

ties of granite residual soil. Adv Mater Sci Eng 3:1–13. https://

doi. org/ 10. 1155/ 2022/ 95422 58

Zhang JK, Su PD, Wen KJ, Li YD, Li L (2020) Environmental impact

and mechanical improvement of microbially induced calcium

carbonate precipitation-treated coal fly ash–soil mixture. Environ

Geotech 35:1–11. https:// doi. org/ 10. 1680/ jenge. 19. 00125

Zhao Q, Li L, Li C, Li M, Amini F, Zhang H (2014) Factors affecting

improvement of engineering properties of MICP-treated soil cata-

lyzed by bacteria and urease. J Mater Civ Eng 26(12):04014094.

https:// doi. org/ 10. 1061/ (ASCE) MT. 1943- 5533. 00010 13

Publisher's Note Springer Nature remains neutral with regard to

jurisdictional claims in published maps and institutional affiliations.

Springer Nature or its licensor (e.g. a society or other partner) holds

exclusive rights to this article under a publishing agreement with the

author(s) or other rightsholder(s); author self-archiving of the accepted

manuscript version of this article is solely governed by the terms of

such publishing agreement and applicable law.

A preview of this full-text is provided by Springer Nature.

Content available from Environmental Earth Sciences

This content is subject to copyright. Terms and conditions apply.